The discovery of the Ojak gas field led to the establishment of the Turkmen gas industry center in Gazodjak, near the village of Shikharyk, in 1966. By the end of 1970, 19 major and minor gas and gas condensate fields had been discovered in Southeast and Northeast Turkmenistan. Among them, the Kukurtli and Maysk (Minara) gas condensate and gas fields were put into operation in 1970.

From 1971 to 1976, several gas condensate fields were developed in Eastern Turkmenistan, including the North Ojak field with modest reserves and the Naip field with large reserves, as well as the massive gas fields of Eastern (Shehitli) and Western (Jojukly) Shatlyk in 1973.

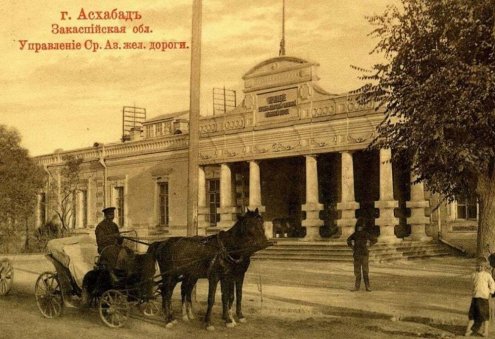

As a result, the number of fields in operation during this period increased to seven, and natural gas production in 1976 rose 4.7 times compared to 1970. That year also saw the construction of the main gas pipeline from Maikop to Ashgabat and Buzmein, which began from the Maikop gas field discovered in 1964. This route allowed natural gas to be transported to Ashgabat.

The Ojak gas condensate field was the first to use the simultaneous-separation exploitation method (SSEM) in the world. It was demonstrated that this method reduces the cost of hydrocarbon production by cutting down on operational and maintenance expenses, accelerates resource development, and increases the possibility of bringing new productive layers into operation.

This method was applied in the development of the Kukurtli and Naip multi-layered gas condensate fields, which reached their projected capacity 3-4 years ahead of schedule. In exploratory and production wells at these and other multi-layered fields, casing columns with a diameter of 148 millimeters were replaced with 168-millimeter columns, resulting in a 50-70% increase in well productivity.

It should also be noted that at three gas processing facilities for the Kukurtli, Ojak, and Naip fields, separate technological lines were built for each production well. However, at subsequent gas processing facilities for the Ojak and Naip fields, several wells were connected to a single technological line, saving hundreds of tons of metal.

For the successful implementation of the SSEM method and the production of tens of billions of cubic meters of natural gas for the national economy, the group of specialists from the production association "Türkmengazsenagat" was awarded the State Prize of Turkmenistan in Science and Technology in 1972.

While the aforementioned method of simultaneous-separation exploitation of multiple productive horizons in multi-layered fields had its practical drawbacks, they were manageable. For instance, accurately determining the operating mode of wells with two productive layers simultaneously (such as measuring the volume of gas from each layer and pressure in the wellbore) was impossible with conventional methods. This led to the need for new approaches to monitor layer performance. Additionally, to enhance field development efficiency, rational use of the method, and improve gas productivity, numerous effective proposals and methods were implemented through the joint efforts of enterprise specialists and scientific researchers. These advancements have allowed the extraction and supply of tens of billions of cubic meters of natural gas, surpassing the project's planned volumes.

By Oraznazar Heshdekov

Originally published in Nebit-Gaz newspaper, June 4, 2024.